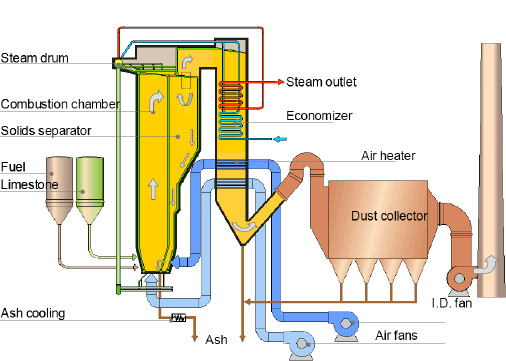

Water Tube CFB Boiler Main Components

Drawing upon its extensive technical expertise and manufacturing experience, ZBG developed the Circulating Fluidized Bed Boiler, that is CFB boiler, which is widely used in industries and power plants. Here we’ll introduce the typical components of CFB boilers:

Wind box and grid nozzle: primary air is fed into wind box.Air is equally distributed on furnace cross section by passing through the grid nozzle. This will help mixing of air and fuel for completed combustion

Bottom ash drain: coarse size of ash that is not take away from furnace by fluidizing air will be drain at bottom ash drain port locating on grid nozzle floor by gravity. Bottom ash will be cooled and conveyed to silo by cooling conveyor.

HP Blower: supply high pressure air to fluidize bed material in loop seal so that it can overflow to furnace Rotameter Supplying of HP blower to loop seal

Cyclone separator: located after furnace exit and before convective part.use to provide circulation by trapping coarse particle back to the furnace. Fluidized boiler without this would be BFB not CFB

Evaporative or Superheat: Wing Wall located on upper zone of furnace, it can be both of evaporative or SH panel lower portion covered by erosion resistant materials

Fuel Feeding system: solid fuel is fed into the lower zone of furnace through the screw conveyor cooling with combustion air. Number of feeding port depend on the size of boiler

Refractory: refractory is used to protect the pressure part from serious erosion zone such as lower bed, cyclone separator

Solid recycle system (Loop seal): loop seal is located between dip leg of separator and furnace. Its design physical is similar to furnace which have air box and nozzle to distribute air. Distributed air from HP blower initiate fluidization. Solid behave like a fluid then over flow back to the furnace.

Lime stone and sand system: lime stone is pneumatically feed or gravitational feed into the furnace slightly above fuel feed port. the objective is to reduce SOx emission.Sand is normally fed by gravitation from silo in order to maintain bed pressure. Its flow control by speed of rotary screw.

Want to know more about CFB Boiler, Want boiler from 1 ton - 400 ton? Contact zg@zzboiler.com or visit https://www.zgindustrialboiler.com.