Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

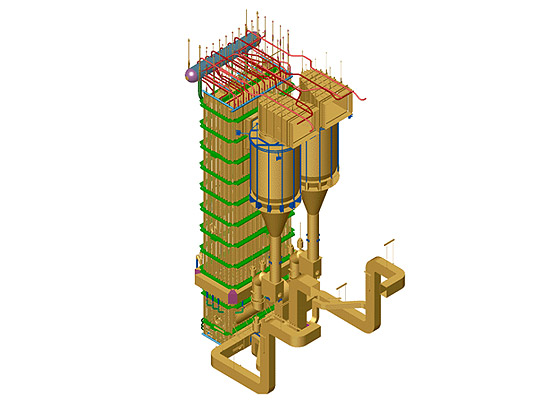

CFB Power Plant Boiler

Circulating fluidized bed power plant boiler inherits the advantages of CFB boiler such as high combustion efficiency, energy saving, fuel flexibility, low NOx, SOx emission, which performs as a kind of large scale heating equipment applied in thermal power plant and other industries for power generation.

-

CAPACITY

20-400 t/14-280 MW

-

Pressure

≤9.81MPa

-

Fuel

Coal, Biomass Fuel

-

Application

Power Plant, Central Heating, Utility

National patent technology, authoritative technical support

Adopts the latest scientific and technological achievements of Tsinghua University, which was listed as the State Education Commission major scientific and technological projects, the Ministry of Science and Technology "national scientific and technological achievements to promote the plan."

Fuel saving

The coal saving of CFB power plant boiler could reach 3-5%.Low bed pressure running, it can save the power consumption of the fan by more than 20%. Coal consumption decreased by more than 3% during running of the boiler.

Low-wear, maintenance costs saving

Low bed pressure operation, low flow speed of flue gas, its heating surface has good durability and almost no wear at all. It means our boiler owner can save part of maintenance costs. Additional, its operation time can up to 8,000 hours annually in power plants.

Fuel adaptability

Widely fuel availability is CFB power plant boiler’s another advantage. Provided more fuel choices, boiler users tend to burn low quality coal or biomass fuels to save its fuel expense. CFB power plant boiler can burn a wide variety of solid fuels, even including low value coal fuel, such as anthracite, bituminous, lignite, wood residue, etc.

| Model | Rated Steam Capacity |

Rated Steam Pressure (bar) |

Superheated Steam Temperature (℃) |

Feeding Water Temperature (℃) |

Designing Fuel | |

| t/h | BHP | |||||

| ZG-35/3.82-M | 35 | 2681 | 38.2 | 450 | 105 | Anthracite coal |

| ZG-45/3.82-M | 45 | 3447 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-50/3.82-M | 50 | 3830 | 38.2 | 450 | 105 | Anthracite coal |

| ZG-75/3.82-M | 75 | 5745 | 38.2 | 450 | 105 | Brown coal |

| ZG-75/5.29-M | 75 | 5745 | 38.2 | 485 | 105 | Bituminous coal |

| ZG-90/3.82-M | 90 | 3894 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-110/6.5-M | 110 | 8426 | 65 | 485 | 105 | Bituminous coal |

| ZG-130/9.8-M | 130 | 9958 | 98 | 540 | 150 | Bituminous coal |

| ZG-150/9.8-M | 150 | 11490 | 98 | 540 | 215 | Brown coal |

| ZG-240/9.81-M | 240 | 18384 | 98.1 | 540 | 215 | Brown coal |

| ZG-280/9.81-M | 280 | 21448 | 98.1 | 540 | 215 | Brown coal |

| Model | Rated Steam Capacity |

Rated Steam Pressure (bar) |

Superheated Steam Temperature (℃) |

Feed Water Temperature (℃) |

Fuel Type | |

| t/h | BHP | |||||

| ZG-15/3.82-M | 15 | 1149 | 38.2 | 450 | 105 | Anthracite coal |

| ZG-16/3.82-M | 16 | 1226 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-20/3.82-M | 20 | 1532 | 38.2 | 485 | 105 | Anthracite coal |

| ZG-25/3.82-M | 25 | 1915 | 38.2 | 450 | 105 | Brown coal |

| ZG-35/3.82-M | 35 | 2681 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-40/3.82-M | 40 | 3064 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-45/3.82-M | 45 | 3447 | 38.2 | 450 | 105 | Bituminous coal |

| ZG-50/5.29-M | 50 | 3830 | 52.9 | 450 | 105 | Bituminous coal |

| ZG-55/3.82-M | 55 | 4213 | 38.2 | 450 | 105 | Brown coal |

| ZG-65/5.29-M | 65 | 4979 | 52.9 | 450 | 105 | Brown coal |

| ZG-75/3.82-M | 75 | 5745 | 38.2 | 450 | 105 | Brown coal |

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China