Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

Palm Oil Plant

We know during the palm oil processing, the residue from the press consists of a mixture of fibre and palm nuts in palm oil plant. Palm kernel shells are remnants of the palm oil refining process and have long been abandoned. Until a cement plant in Malaysia uses palm shells as biofuel, it mixes with coal to produce heat. Today, many European countries, including the United Kingdom, the Netherlands, Italy and other places began to try to put palm shell mixed coal fuel together to provide energy to alleviate the rising costs of fuel and reduce carbon dioxide emissions.

Boiler in Palm Oil Plant

Large-scale palm oil plant use the recovered fibre and nutshells to fire the steam boilers for power generation and steam supplying in the palm oil mill. The super-heated steam is then used to drive turbines to generate electricity for the mill. Compared to other residues from the industry, it is a good quality biomass fuel with uniform size distribution, easy handling, easy crushing, and limited biological activity due to low moisture content. Therefore, using the palm kernel shell as fuel in palm oil plant can largely reduce the fuel cost.

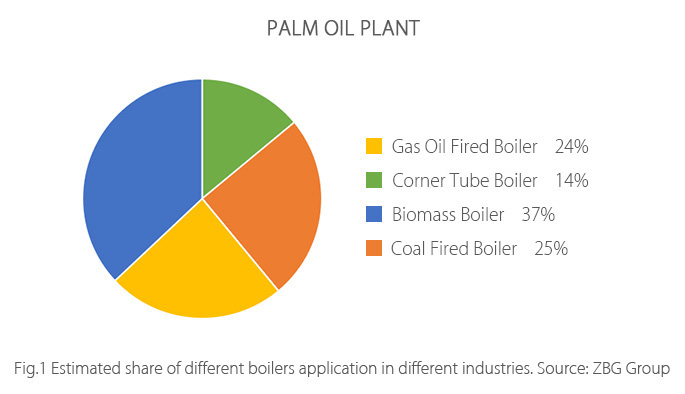

Which type of boilers apply to this industry ?

-

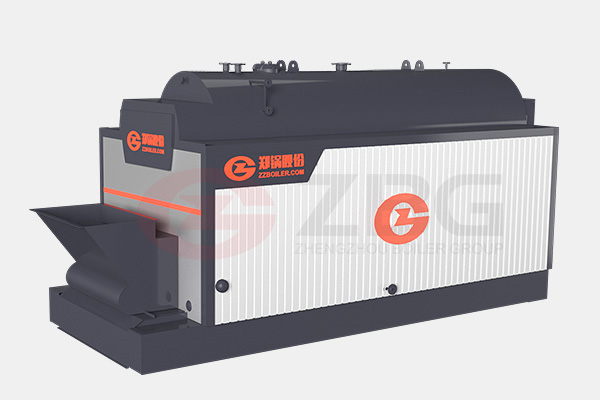

DZL Packaged Boiler

DZL Packaged Boiler

Capacity: 2-10 t/1.4-7 MW

Pressure: ≤1.6MPa

Fuel: Wood, Rice Husk, Bagasse, Straw, Sawdust -

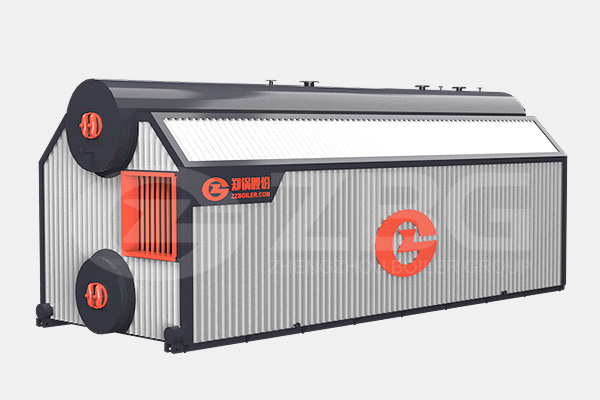

SZL Water Tube Boiler

SZL Water Tube Boiler

Capacity: 6-30 t/ 4.2-21 MW

Pressure: ≤1.6MPa

Fuel: Biomass Fuel, Rice Husk, Bagasses -

SZS Gas & Oil Water Tube Boiler

SZS Gas & Oil Water Tube Boiler

Capacity: 4-90 t /2.8-63 MW

Pressure: ≤3.82MPa

Fuel: Natural Gas,Biogas,Heavy Oil,Light Oil -

Biomass Power Plant Boiler

Biomass Power Plant Boiler

Capacity: 10 - 75 t/ 7-52.5 MW

Pressure: ≤5.29MPa

Fuel: Rice Husk, Straw, Wood Pellet, Bagasse

CUSTOMER PROJECTS

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China