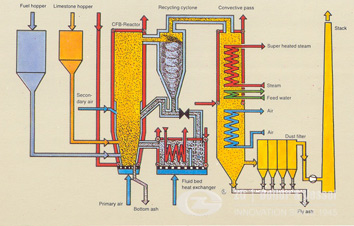

Circulating Fluidized Bed Boiler Combustion System Advantages

CFBC technology, also circulating fluidized bed combustion technology, is widely applied in chemical plant boilers, steel work boilers, power plant boilers and other large scale industrial boilers. CFBC system has been employed for power generation for more than 20 years, and approximately 800 coal-burning CFBC power generating units have been installed and are in operation worldwide. In many industries, circulating fluidized bed combustion boilers are widely used to supply adequate steam or hot water. Why the cfbc system is more and more popular in industries? Because it has many advantages as follow:

High efficiency of cfbc system

The thermal efficiency is the main aspect of fossil fuel-based power generating units. The combustion efficiency is the ability of a furnace to burn carbon. CFBC systems have a special advantage, that they are designed to increase the residence burning time of solid fuel, with the method of allowing for re-circulation of fuel into and through the high-temperature combustion zones. This means that fuels ranging from anthracite to wood can be burnt in appropriately CFBC boilers at high combustion efficiency of up to 99%, which can save many fuel cost than other coal fired boilers.

Fuel flexibility of cfbc system

A major advantage of CFBC system is that it can consume low quality fuels, which could not be used in a packaged boilers, such as chain grate boiler. These fuels are characterized by a high ash or moisture content, low heating value, and low volatile content and thus have lower costs. CFB power palnt boilers can burn all types of coal and a wide range of other fuels with high efficiency.

Environmental protection of cfbc system

Another main advantage of a CFBC boiler is the low emissions of NOx and SO2. The combustion

temperature of a CFBC boiler is 800–900º, which results in a considerably reduced NOx formation. With the limestone injected into the furnace, majority of SO2 formed during coal combustion is captured. Typically, CFBC system can achieve a sulfur removal efficiency of 90% at a Ca/S molar ratio of around 2 and increases to 95% for a Ca/S ratio of 3. For most CFBC boilers, NOx emissions are less than 200 mg/m3.