Pharmaceutical waste incineration boiler

Ⅰ. Overview

Along with the increasing intensity of environmental protection, the various sources of pollution and contamination control methods have become increasingly stringent, many pharmaceutical waste generated have become the object of governance, therefore, these pharmaceutical companies eager to find a effective method of treatment of pharmaceutical waste, can solve the pollution problems and can be used to create effective utilization technology, turning waste into treasure. This article describes the company developed the design of a waste incineration boilers pharmaceutical products to waste as boiler fuel, the burning of waste at the same time using a boiler to produce steam for the pharmaceutical technology use.

Ⅱ.the boiler design parameters:

(1) Rated evaporation capacity: 30t / h

(2) Rated steam pressure: 1.25MPa

(3) Rated steam temperature: 194 ℃

(4) Water Temperature: 104 ℃

(5) cooling air temperature: 30 ℃

(6) discharge rate: 5%

(7) the exhaust gas temperature: 168 ℃

(8) Design thermal efficiency: 80%

Ⅲ.boiler brief

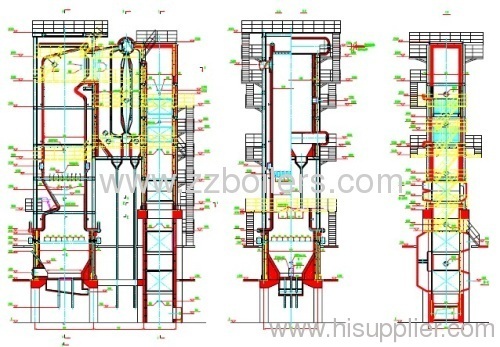

Pharmaceutical waste incineration boiler is based on the characteristics of pharmaceutical waste and design, double-drum boiler, "Ⅱ" type layout of the natural cycle bulk boilers, boiler height (not including canopy) 28400mm, depth of about 17500mm, 9500mm width of about , the drum center elevation 27000mm, 4200mm ignition layer disposed on the elevation, run the operation layer disposed on at elevation 7500mm. The upper part of the main combustion chamber area waste, waste water using a special nozzle from the front wall (four) and both sides of the wall (the one) in the form of mist sprayed into the furnace, the furnace bottom for the secondary combustion zone, a fluidized cloth wind deflector, and isobaric bellows, mainly for waste ignited provide heat, the section of the adiabatic section. The upper part of membrane wall furnace, furnace slag condensate outlet pipe arranged diarrhea, furnace exit to import a bundle of burning ember room, boiler convection bank Expansion mode uses the upper and lower drum links, rear flue arrangement of two economizer and the air preheater.

Furnace

Composed by the membrane wall furnace, front elevation 10790mm membrane wall tube furnace arch-shaped and folded at its layout on waste imports, roof membrane wall connected with the drum, after the membrane wall tube with bull nose and diarrhea in the furnace outlet tube into the cold residue on the drum with the connection. The lower section of the furnace combustion furnace wall formed by the heavy and is not arranged any heating surface, to provide a sufficient temperature waste combustion, furnace bottom provided with a flow of the air distribution plate and the other components bellows pressure fluidized bed combustion system. In order to ensure full combustion boiler using one, two, three wind configurations, the primary air is supplied by the isobaric bellows, located in the lower part of the secondary air suspension, located in the upper chamber tertiary air.

Drum and convection bank

The drum diameter 1400mm, lower drum diameter 1000mm. Supported on the beam on the drum, the drum by the convection tube hanging down on the drum, down free expansion. Installed inside the drum to the water, steam separation devices, continuous sewage, phosphate dosing tubes and other devices installed inside the drum under periodic sewage plant. Convection tube and the lower upper drum Expansion.

Economizer

Economizer arranged in the tail of two flue, two-line layout are economizer. With inlet and outlet header, hot water from the economizer outlet header pipe connecting lead supremacy drum.

Air preheater

Air preheater arranged in the tail of two flue, are used tubular air preheater, flue gas inlet casing with wear, the air-side sealing device used to prevent air short circuit, therefore, the air preheater utilization factor is higher. First-class air preheater preheating primary air, secondary air preheater preheating two or three times the wind, each level has two return, both for the countercurrent heat exchanger, two each with a wind turbine.

Steel frame and platform escalators

30 tons of steam pharmaceutical waste incineration boiler steel frame with all-steel, respectively Ⅰ, Ⅱ, Ⅲ, Ⅳ number of two, composed of a total of eight columns, the length of the four. Ⅰ, Ⅱ number length four columns supporting and Elevation 4200mm boiler basis, through the embedded steel on the basis of the underlying connection with its top with roof pillar framework for hanging furnace water wall tube model. Ⅲ, Ⅳ number short four columns supporting and Elevation 11000mm boiler basis, through the embedded steel base and foundation connections, supports, economizer and air preheater heating surface and the rear wall of the furnace. The testing, inspection door hole, drum and set top box into the hole, hand holes are arranged at the platform to facilitate the monitoring, inspection and repair.

Boiler furnace wall, insulation and outsourcing

Boiler furnace combustion zone using heavy furnace wall, furnace chamber membrane wall and burn out left and right side, front and rear pattern waterwall section topical silicate insulation cotton, cotton insulation outside smear mud stone, convection flue tubes are heavy and tail region furnace wall. Since boiler semi-open layout, the entire boiler used in all corrugated outer color plates for outsourcing.

30 tons of steam boiler has been designed pharmaceutical waste incineration completed and put into operation, as my company's new research and development of environmentally friendly boilers, will be able to open in the field of treatment of pharmaceutical waste a new world.