Brief Introduction of Autoclaved Aerated Concrete Plant Equipment

In recent year, autoclaved aerated concrete (AAC) is more and more used into construction industry as a new kind of green building materials. And more people invest in AAC Plant. We are specialized steam boiler and autoclave for AAC Plant supplier, offering autoclaved aerated concrete plant with 50000, 100000, 150000, 200000, 250000, 300000m3 capacity annually, and also we design and manufacture as per clients' requirement.

AAC Block Plant Equipment List:

1. Cutting equipment: tilting crane, cutter.

2. Proportioning equipment: electronic measuring scale, slurry beating machine, slurry storage tank, slurry mixer.

3. Pouring and autoclave equipment: aluminum powder mixer. Pouring mixer, mould, side plate, autoclave truck, carrier car.

4. Conveying equipment: semi-product crane, end product crane.

5. Pressure vessel equipment: boiler, autoclave.

6. Crushing equipment: ball miller, crusher.

7. Transportation equipment: crane, lifting machine, feeder, belt conveyor, slurry pump, screw conveyor.

8. Environment protect equipment: dust remover

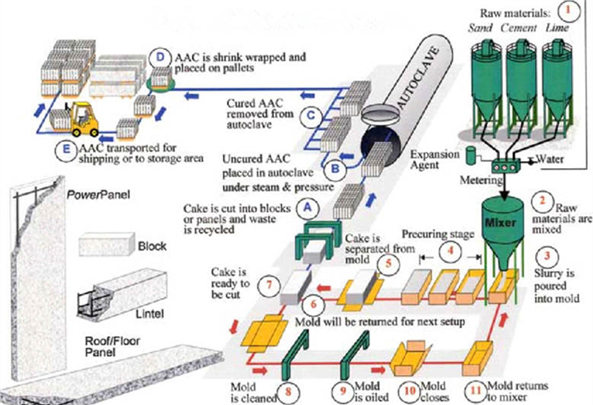

The aac block machine production line process:

1.Aerated concrete/aerated blocks raw material preparation and storage

2.Aerated concrete/aerated blocks Ingredients, mixing, pouring

3.Aerated block static stop maintenance

4. Aerated block cutting

4. Aerated block cutting

5.Aerated block coding ,autoclave autoclaved and finished product

What are the advantages of using AAC Block?

1. AAC Block making plant Consumes Fly ash, which is a big problem for thermal power plants to dispose. It is environment friendly, because of no need of burning.

2. Higher strength, best thermal insulation & excellent sound absorption, vibration resistance compared to red bricks. The AAC product’s lightweight and easy workability means that is very quick to install on site and transportation with lesser brakeage.

3. AAC blocks made walls can be left exposed (without Plaster) and gains strength over time. It saves structural cost by 35% and recycling of breakage, rejects also

4. AAC products are not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions.

5. AAC Block does not have any toxic substances or emit odors. Its production, management and disposal do not represent any health risks or damage to the environment. Its production process develops non-toxic gases.

6. AAC blocks are bigger in size then conventional bricks, resulting in lesser number of joints. Less joints result in lesser quantity of mortar required, resulting in saving of mortar.