Deaerator In Boiler Feedwater System

Feedwater will often have oxygen dissolved in it at objectionable levels. The oxygen comes from air in leakage from the condenser, pump seals, or from the condensate itself. The oxygen is mechanically removed in a deaerator.

What is a deaerator?

A deaerator is mechanical device that remove dissolved gases from boiler feed water. Deaeration protects the steam system from the effects of corrosive gases. It accomplishes this by reducing the concentration of dissolved oxygen and carbon dioxide to a level where corrosion is minimized. A dissolved oxygen level of 5 parts per billion (ppb) or lower is needed to prevent corrosion in most highpressure (>200 pounds per square inch) boilers. While oxygen concentrations of up to 43 ppb may be tolerated in low-pressure boilers, equipment life is extended at little or no cost by limiting the oxygen concentration to 5 ppb. Dissolved carbon dioxide is essentially completely removed by the deaerator.

Types of Deaerator

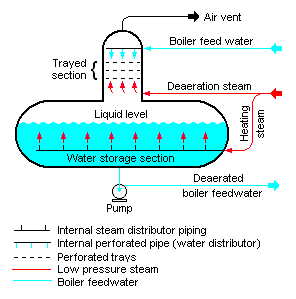

The tray-type (also called the cascade-type) includes a vertical domed deaeration section mounted on top of a horizontal cylindrical vessel which serves as the deaerated boiler feedwater storage tank.

The spray-type consists only of a horizontal (or vertical) cylindrical vessel which serves as both the deaeration section and the boiler feedwater storage tank.

How does a Deaerator work

Makeup water and pumped returns are sprayed into the deaerator tray section through a stainless steel spray nozzle. The spray nozzle provides a thin conical sheet of water that condenses the vapors while permitting oxygen to exit through the vent. The partially deaerated water then begins to cascade through the trays.

The combined makeup and pumped returns are heated with steam that flows upward through the stainless steel trays. The steam vigorously scrubs the dissolved oxygen from the makeup and pumped returns. The trapped returns enter the deaerator storage section. Steam from the returns also flows upward through the deaerator trays, while the water drops to the water level in the deaerator storage section.

The fully deaerated water remains in the deaerator storage section for use by the boiler, while the excess steam flows into the deaerator tray section. Non-condensable gases enter the vent and pass to the atmosphere.

If you have problems in boiler selection, purchase, price, please contact zg@zzboiler.com or call 86-371-86062323 !