Fully Automatic Fuel Gas Boiler Structural Features

WNS series oil and gas boilers are horizontal internal combustion three pass complete wet back fire-tube boilers, a high tech product developed by our company based on imported Germany technology, as an integration of electronics, combustion and heat exchange.

Fully Automatic Fuel Gas Boiler Structural Feature

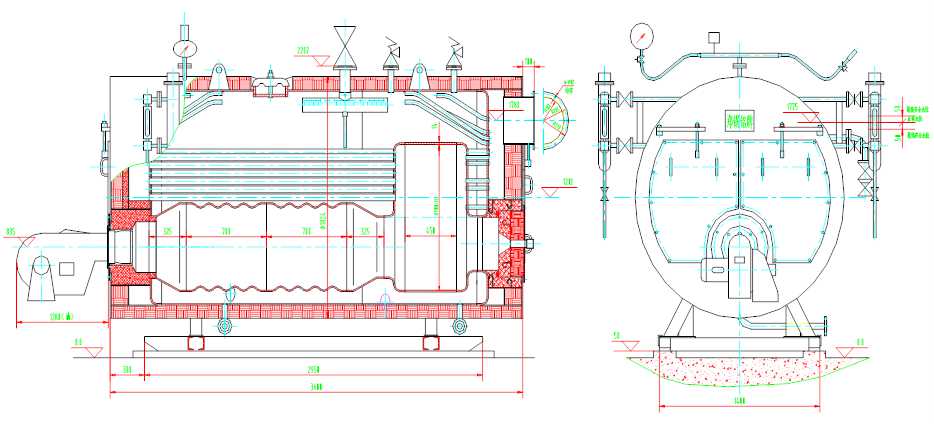

WNS Gas & Oil Fired Boiler Structural Diagram

Safe and Reliable

Main boiler utilizes an all wet back structure. As the shell diameter is relatively large, the boiler water volume is higher, with good safety characteristics.

The boiler model is especially well suited to positive pressure operation and has good blast resistance and excellent insulation

Unique design with double inner and outer doors for the front and rear smoke box structure, which is highly ingenious in separating the functions for heat resistance and heat insulation.

Stainless steel serves as lining in the front smoke box, completely eliminating the possibility of heat resistant materials peeling off

Advanced and complete independent safety control technology and high quality components ensure safe and reliable boiler operation

Clean and Environmentally Friendly, High Efficiency and Conserving Energy

Boiler uses insulating protective materials, with good heat insulation effectiveness. Surface temperature is only higher than room temperature by 5°C, limiting heat loss, while also cutting off the noise generated inside the boiler by combustion

Utilizes an internationally renowned imported fully automatic burner, achieving highly efficient boiler combustion, conserving fuel and reducing emissions of pollution, noise and waste gas.

Uses high efficiency heat transfer corrugated tube components, that increase heat transfer with significant energy conservation

Uses natural circulation method resulting in low power loss and a relatively simple boiler system

Energy conservation device is configured at the back and can further boost boiler thermal efficiency by 3%~7%

Compact Structure, Easy Maintenance

Uses integrated fast-assembly design

Uses high efficiency heat transfer corrugated tube components with very good thermal expansion characteristics, which can prevent deformation of heating surface. Corrugated tube heat transmission coefficient is far higher than that of flat tubes with the same heating surface, thereby reducing boiler volume.

Burner and tube instruments are integrated, saving on boiler room occupied area as well as lowering installation costs and infrastructure investment.

Easy to maintain: Only need to open the front and rear smokebox doors for maintenance