Steam Boiler or Steam Generator

Some clients send inquiry for steam generator to our company. However, as an boiler manufacturer, we mainly provide industrial boiler solutions, like steam boiler, hot water boiler, power plant boiler, not including the steam generator. Some of them are confused at steam boiler and steam generator, think that they might be same. Even thought the two have some same characteristics, they are quite different in some aspect.

Steam Boiler VS Steam Generator

The steam generator or boiler is an integral component of a steam engine when considered as a prime mover. However it needs be treated separately, as to some extent a variety of generator types can be combined with a variety of

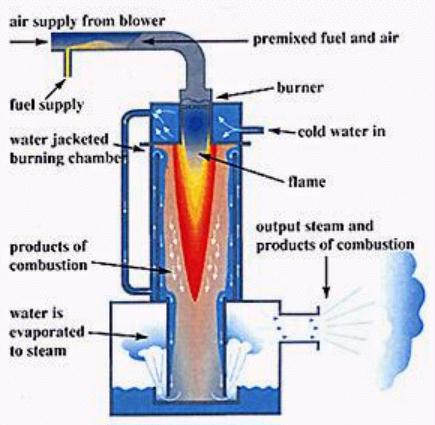

engine units. A boiler incorporates a firebox or furnace in order to burn the fuel and generate heat. The generated heat is transferred to water to make steam, the process of boiling. This produces saturated steam at a rate which can vary according to the pressure above the boiling water. The higher the furnace temperature, the faster the steam production. The saturated steam thus produced can then either be used immediately to produce power via a turbine and alternator, or else may be further superheated to a higher temperature.

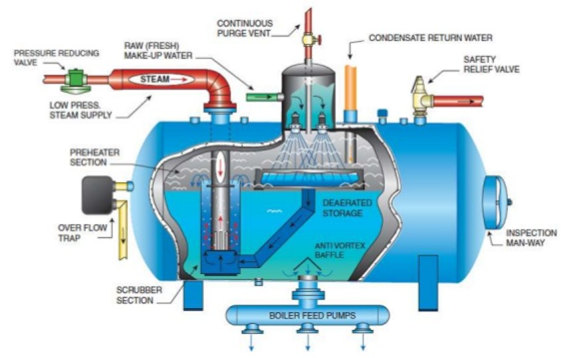

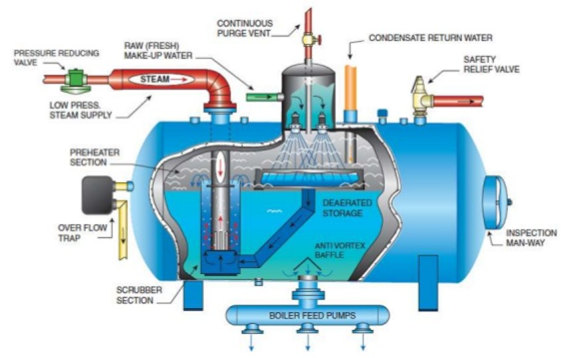

What is Steam Boiler: The steam boiler (including the steam generator boiler) is connected to the consumers through the steam and condensate piping. When the steam is provided to the consumers, it condensates and thereby releases a high amount of latent heat described above. The condensate (hot water) can then be returned to the feed water tank, from where it again is pumped and provided to the steam boiler.

What Is Steam Generator: A steam generator is a form of low water-content boiler, similar to a flash steam boiler. The usual construction is as a spiral coil of water-tube, arranged as a single, or monotube, coil. Circulation is once-through and pumped under pressure, as a forced-circulation boiler. The narrow-tube construction, without any large-diameter drums or tanks, means that they are safe from the effects of explosion, even if worked at high pressures.

In the fire-tube steam boilers, from the surface of a large volume of feed water, steam is evaporated. This boiling process is heated by the wall of the combustion chamber (the radiant part) and by the exhaust gasses passing through a bundle of so-called fire-tubes or smoke-tubes forming the the convection part of the boiler.

In the steam generator boiler the operation is quite different. The feed water and steam are in the principle passing through one long tube - designed as a number of winded-up tube coils that are being serially connected.

Industrial Steam Boiler Manufacturer

We provide water tube steam boiler and fire tube steam boilers to meet different applications in textile plant, industrial processing, food & beverage, paper plant, diary industry, chemical industry, hospital, garment factory, mining industry, etc. If you need help in boiler selection and quotation, please contact zg@zzboiler.com or call 86-371-86062323 !