What Waste Heat Boiler Is For Carbon Plant

Waste heat that produced in carbon plant can be recycled and utilized as fuel in a waste heat recovery boiler. The carbon rotary kiln waste heat boiler is the very equipment to turn the waste heat into energy and bring benefits for the industry as well.

Successful application of carbon kiln waste heat boiler in the carbon production process helps to reduce production costs, improve economic efficiency of enterprises, at the same time, it can reduce the environment pollution, so as to realize economic and social benefits.

People should pay attention if they want to purchase a waste heat steam boiler, some parameters such as original parameter and boiler parameter are very essential. The original parameter should consider the amount of inlet flue gas, the inlet flue gas temperature and outlet flue gas temperature design; the boiler parameter should consider the rated steam evaporation, superheated steam outlet temperature, the superheated steam outlet pressure, drum operating pressure and feedwater temperature.

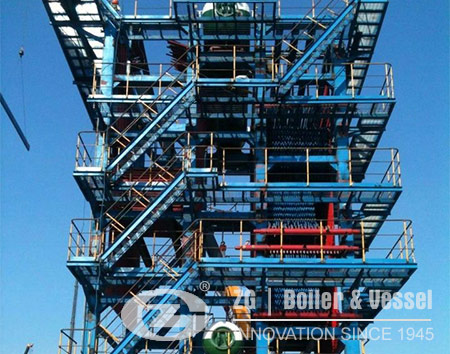

Carbon rotary kiln waste heat boiler is a vertical type water tube boiler, with invert π type arrangement. The flue gas exhausted from combustion chamber goes through the waste heat boiler, after dust-catching treatment, it is finally exhausted into the atmosphere. Some of the generated steam is used for supplying production, but mostly is for power generation. We had a 35 ton carbon kiln waste heat boiler in Kazakhstan. Petroleum Coke Calcined Plant---the National Key Project in Kazakhstan is totally designed by a China’s company. After carbon kiln flue gas entering into boiler, steam will be generated, and the plant mainly utilize the steam for power generation. The project main equipment is composed by 2.45MP, 35T*2 medium-pressure boilers and 4kw*4 generators.