Why Our Boilers Are Designed As Wet-Back Boilers: Dry-Back Boiler VS Wet-Back Boiler

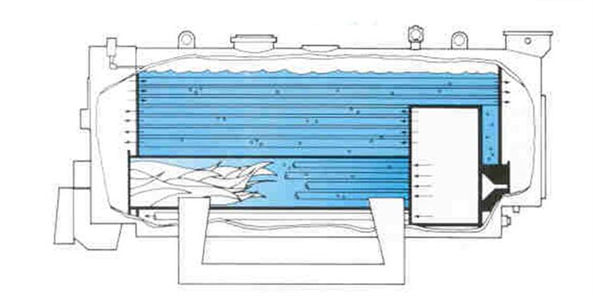

Reversal chamber is the posterior portion of the boiler combustion chamber through which the flue gases travel from the furnace’s first pass to the second pass tubes. And based on the construction of reversal chamber, boilers can be classified into wet-back boilers and dry-back boilers. In general, our boilers, like the WNS gas and oil fired boiler, are designed as wet-back structure.

Disadvantages of Dry-back boilers

Dry back boilers are subject to deteriorating rear refractory, leaking baffles, leaking door seals, and often found with a heat-stressed rear tube sheet. Fragile refractory baffling and door seals will require continuous monitoring, maintenance, and replacement, costing thousands of dollars in materials and specialized labor costs over the life of the boiler. In addition, broken baffles and leaking seals will short-circuit the boiler’s gas flow, causing high stack temperatures and lowering efficiency until repairs can be made. This can bring your production process to a costly halt.

Why we design wet-back boilers

Those frustrating problems brought by dry-back boilers can be resolved by our WNS Wet-back designed boilers. WNS gas and oil fired boiler has a full wet back radiant heat transfer area that promotes superior internal water circulation and rapid heat absorption, rear tube sheet, and allows tubes to expand and contract at its own rate without tube sheet stress. The only rear refractory is a man way plug which allows access to the furnace for inspection.

Anyway, we can see the wetback boiler’s overwhelming advantages:

Offer far fewer maintenance concerns:

- No rear door refractory to repair

- No refractory baffling to burn-out

- Far less thermal stress on tube sheets, and tube ends

Don’t require proprietary parts

Offer maximum sustainable efficiency: Maintenance-free water backed turnaround provides better heat absorption at the most critical heat transfer point.

Bottom Line: Wetback boilers deliver substantial maintenance and fuel cost savings over the life of equipment ownership, with minimal equipment downtime.

More information, visit https://zgindustrialboiler.com/ or consult zg@zzboiler.com or call 86-371-86062323 !