Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

Sugar Mill

We supply types of boilers for the generation of steam and power required for the operation of sugar mill.

Electricity and steam are almost required in every step of raw sugar process, especially in juice extraction, clarification, evaporation and sugar drying, good quality steam takes a crucial role. Thus selection of steam boilers becomes very important for sugar plant.

Boiler in Sugar Mill

In fact, most cane sugar factories have been designed to be energy self-sufficient, with sugar as the primary product and bagasse as the primary fuel. A bagasse-fired cogeneration system, made of steam boilers and steam driven turbo-alternators, provides all the steam and electricity needed to run the cane mills and factory, leaving little surplus bagasse. The bagasse is fired in the boiler for producing steam at high pressure, which is extracted through various single high capacity turbines and used in the process.

ZBG Group, a leading boiler manufacturer and supplier, can supply sugar mills with high quality steam boilers. Bagasse fired boilers, coal steam boilers, bagasse fired CFB boilers, or whatever, our skilled engineers are always ready to create a solution that is perfectly tailored to your specific requirements and processes.

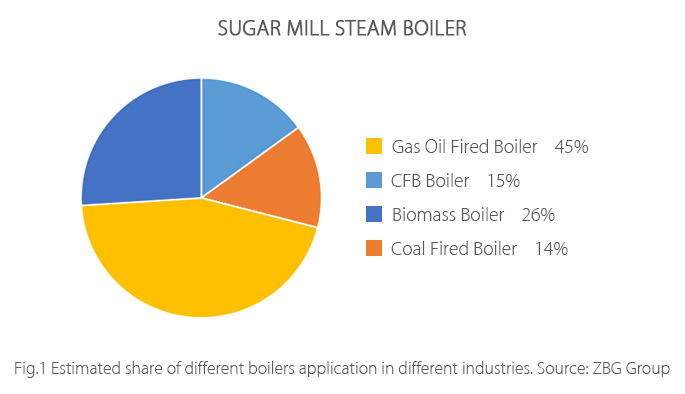

Which type of boilers apply to this industry ?

-

SZL Water Tube Boiler

SZL Water Tube Boiler

Capacity: 6-30 t/ 4.2-21 MW

Pressure: ≤1.6MPa

Fuel: Biomass Fuel, Rice Husk, Bagasses -

DZL Packaged Boiler

DZL Packaged Boiler

Capacity: 2-10 t/1.4-7 MW

Pressure: ≤1.6MPa

Fuel: Wood, Rice Husk, Bagasse, Straw, Sawdust -

Biomass Fired CFB Boiler

Biomass Fired CFB Boiler

Capacity: 20-280 t/ 14-196 MW

Pressure: ≤5.29MPa

Fuel: Biomass,Rice Husk,Palm Kernel -

DHL Series Coal Fired Corner Tube Boiler

DHL Series Coal Fired Corner Tube Boiler

Capacity: 20-75 t/14-116 MW

Pressure: ≤3.82MPa

Fuel: Bituminous Coal, Anthracite Coal

CUSTOMER PROJECTS

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China