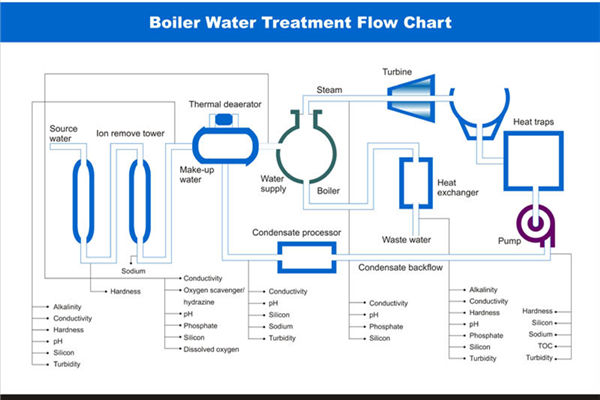

Industrial Boiler Water Treatment: External treatment and Internal Treatment

The water has to be treated to meet boiler feed water criteria. And the treatment and conditioning of boiler feed water must satisfy three main objectives:

•Continuous heat exchange

•Corrosion protection

•Production of high quality steam

Generally speaking, the boiler water treatment for industrial boiler can be divided into external treatment and internal treatment.

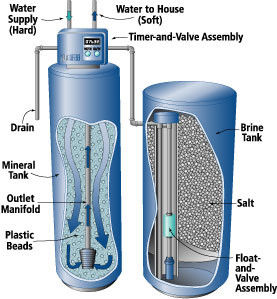

External treatment

External treatment is the reduction or removal of impurities from water outside the boiler. In general, external treatment is used when the amount of one or more of the feed water impurities is too high to be tolerated by the boiler system in question. There are many types of external treatment (softening, evaporation, deaeration, membrane contractors etc.) which can be used to tailor make feed-water for a particular system. Internal treatment is the conditioning of impurities within the boiler system. The reactions occur either in the feed lines or in the boiler proper. Internal treatment may be used alone or in conjunction with external treatment. Its purpose is to properly react with feed water hardness, condition sludge, scavenge oxygen and prevent boiler water foaming.

The water treatment facilities purify and deaerate make-up water or feed water. Water is sometimes pretreated by evaporation to produce relatively pure vapor, which is then condensed and used for boiler feed purposes. Evaporators are of several different types, the simplest being a tank of water through which steam coils are passed to heat the water to the boiling point. Sometimes to increase the efficiency the vapor from the first tank is passed through coils in a second tank of water to produce additional heating and evaporation. Evaporators are suitable where steam as a source of heat is readily available. They have particular advantages over demineralization, for example, when the dissolved solids in the raw water are very high.

Internal treatment

Internal treatment can constitute the unique treatment when boilers operate at low or moderate pressure, when large amounts of condensed steam are used for feed water, or when good quality raw water is available. The purpose of an internal treatment is to

1) react with any feed-water hardness and prevent it from precipitating on the boiler metal as scale;

2) condition any suspended matter such as hardness sludge or iron oxide in the boiler and make it non-adherent to the boiler metal;

3) provide anti-foam protection to allow a reasonable concentration of dissolved and suspended solids in the boiler water without foam carry-over;

4) eliminate oxygen from the water and provide enough alkalinity to prevent boiler corrosion.