5 Ways Help Improve Your Industrial Boiler Efficiency

Industrial boiler efficiency is a very important issue for boiler users. There are many ways to increase boiler efficiency that can be carried out easily. Here are five ways to help improve your boiler efficiency and save your money.

1. Regular Maintenance

The best way to keep your industrial boiler system running efficiently is to have a regular boiler maintenance program. A good maintenance program will slow equipment deterioration, enhance efficiency, maintain reliability, and ultimately reduce operating costs.

2. Boiler burner

No matter how good a boiler burner is, it will deteriorate and lose efficiency over time. If your boiler burner has been badly wear and torn, it is useful to replace a new one. And there are many options for you to consider when considering a replacement, just according to actual need. But if you don’t have a plan to buy a new one, then just retrofit, this also provides big savings.

3. Air preheater

Air preheaters recover waste heat from flue gas and then use it to preheat combustion air. There are two main types of preheaters: recuperators and regenerators. A recuperator system is installed in a boiler stack and transfers heat from outgoing gas to incoming air. A regenerator, on the other hand, includes heat storage sections that transfer heat from flue gas to combustion air.

4. Boiler condensate system

Boiler condensate is essentially hot water, which is what you need to run your boiler. Not recovering it for your industrial boiler system is a waste of energy. A return condensate system can help you recoup condensate’s heat and water, but it has to be carefully matched to your boiler system to guarantee condensate quality. Many modern boilers already include condensate return systems.

5. Boiler Economizers

Boiler economizer is an essential part of a high efficiency boiler. Economizers offer the added benefit of reducing the chance of thermal shock by minimizing water temperature fluctuations. In addition, much like the preheaters, a boiler economizer takes waste heat and transfer it to a boiler’s feedwater, rather than combustion air. Preheated water is obviously closer to the temperature needed to produce steam, so this saves energy when the preheated feedwater enters the steam drum or furnace.

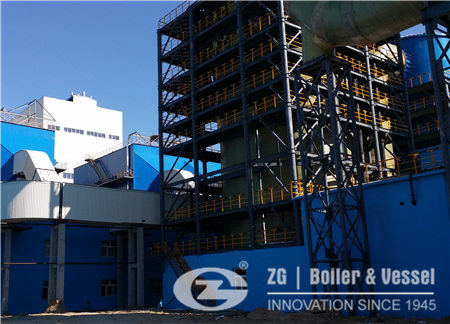

ZG Boiler provides high efficiency and good quality industrial boilers, if you have any need, please contact zg@zzboiler.com or call 86-371-86062323 !